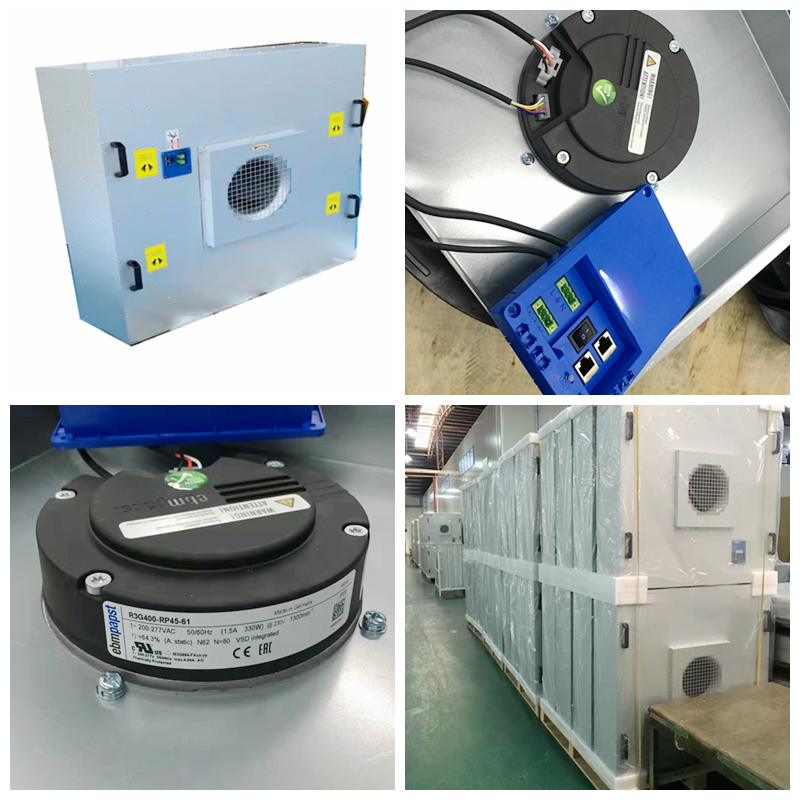

Qianqin Brand Group Control DC Fan Filter Unit (4*4ft) for Clean Room

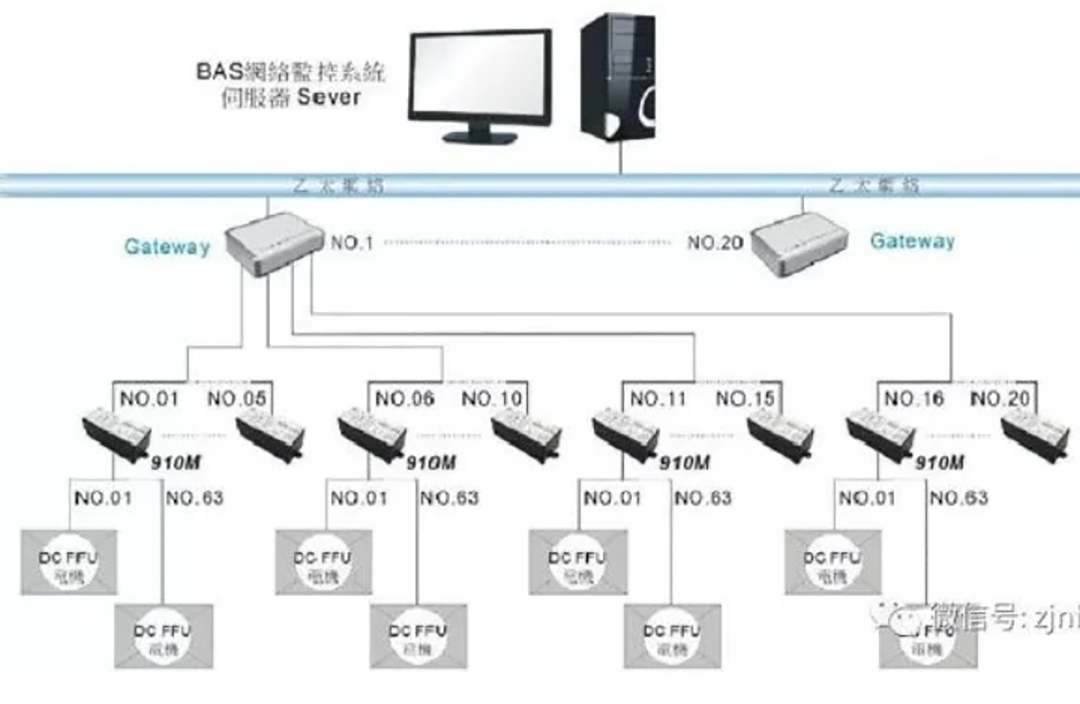

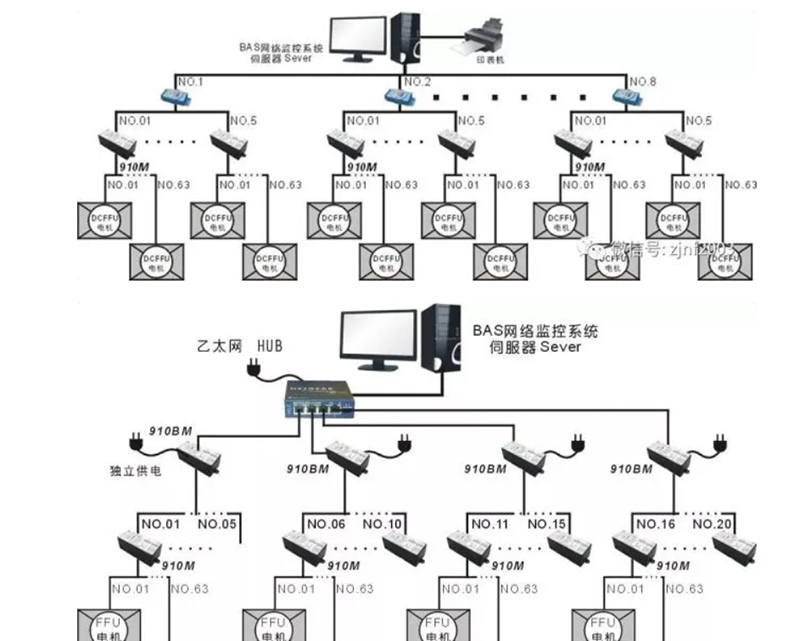

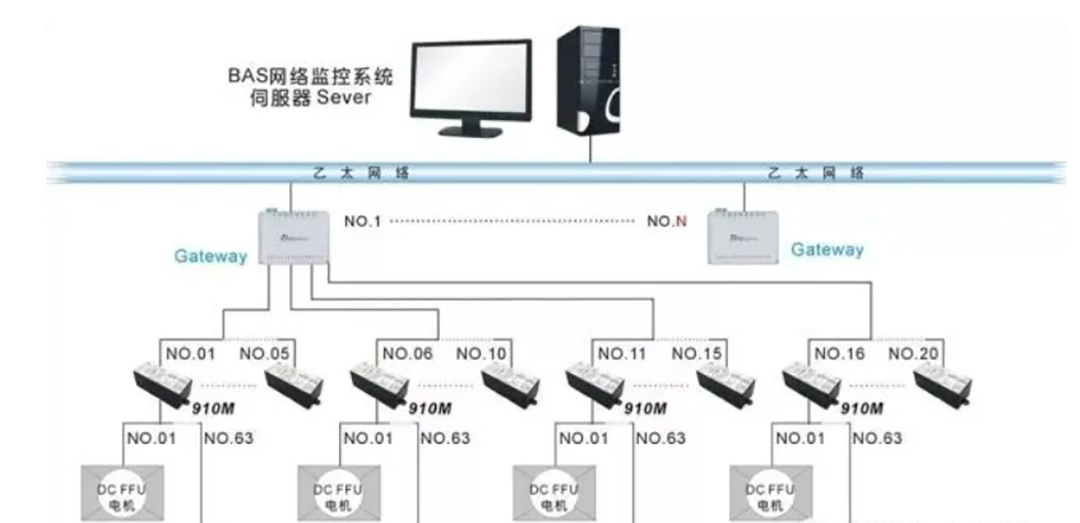

Overall System Architecture Features

1 System advantages:

1.1 Using a server-grade computer, 20 Getways can be connected, and a maximum of 25,200 FFUs can be monitored.

1.2 The three-layer network architecture is adopted to increase the response speed of system monitoring.

1.3 Getway adopts the Ethernet network to the Internet, which can increase the data transmission speed and make the wiring method more flexible.

1.4 Getway adopts RS-485 communication for the lower network, which can increase the system stability, anti-interference ability and increase the wiring length.

2. Advantages of wiring: The system wiring adopts CAT5 8P8C network line, which can increase the stability and reliability of the line. The wire can be processed in the factory according to the required length in advance and then shipped to the site for wiring, saving on-site wiring time and wiring quality issues.

3 Other advantages:

3.1 If 1 Getway loop monitors 1,260 FFUs, and the baud rate is selected as 9600, it only takes 1 minute to complete the polling of 1,260 FFUs. (For the detailed calculation method, see item 5)

3.2 Each FFU controlled by the 910M will be turned on in turn according to different IP addresses, so as to avoid the power system tripping of the plant when the power is turned on at the same time.

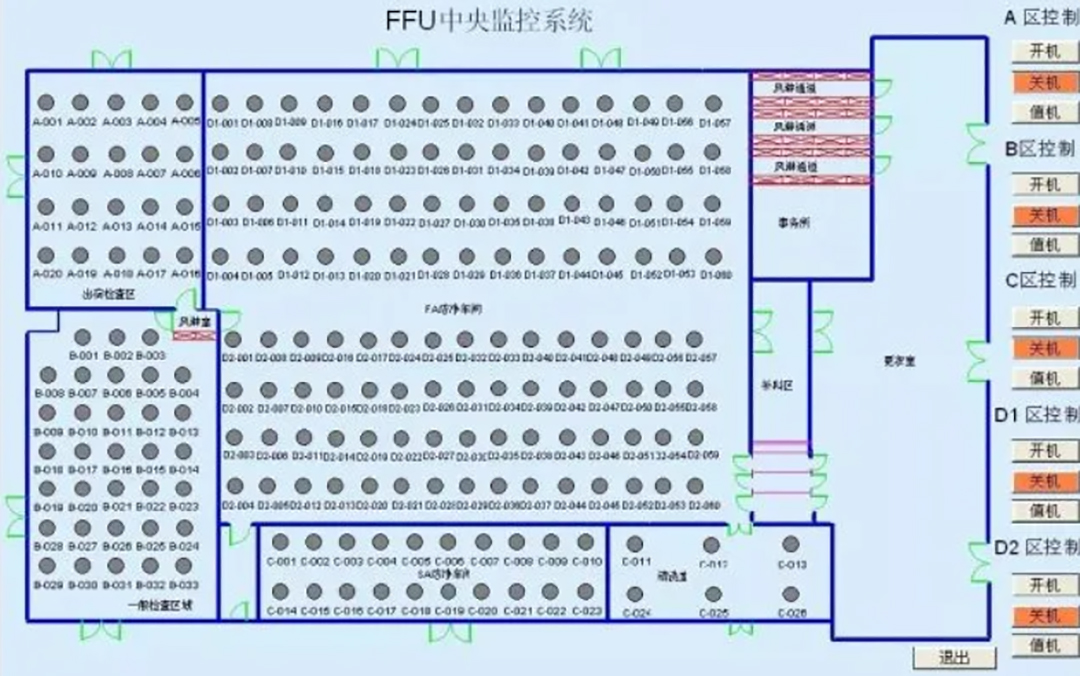

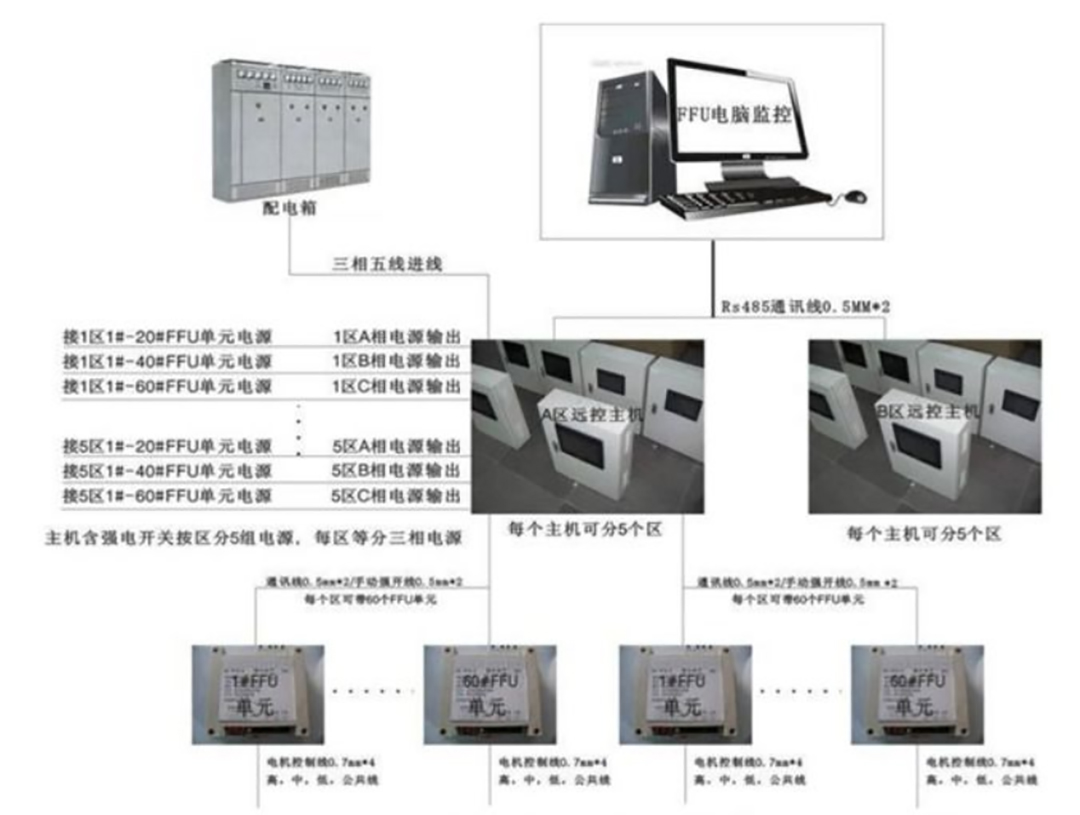

FFU computer control system

The computer is composed of professional FFU monitoring software. The software is divided into the main interface and the sub-interface. The main interface displays the FFU system distribution diagram and partition diagram. The main interface can directly control the partition switch. FFU status and control each FFU control unit.

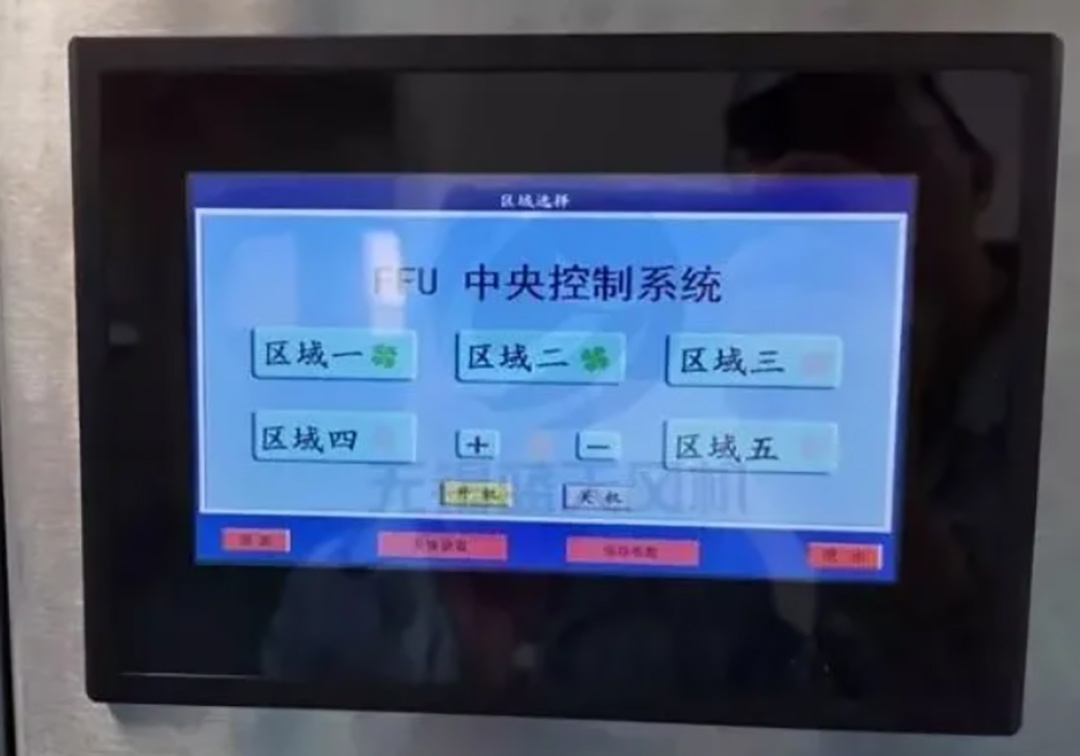

FFU host control system

FFU host controller is the core controller of FFU centralized control system. It adopts touch screen display to realize remote monitoring and adjustment of FFU. It can set and control each FFU control unit, and send and receive signals to the computer. When the system When there is no computer in the configuration or the computer is turned off, the FFU control host can independently complete the setting and control of the entire system.

Getaway Features

1 Communication advantages:

1.1 The isolated Ethernet network is used for upper-end computer communication, which can enhance the electrical isolation capability of each group of Getways, avoid the mutual influence of FFU circuits, and increase the speed of data transmission.

1.2 RS-485 communication is adopted for the communication at the lower end, each Getway has 4 sets of RS-485 PORT, each set of PROT can be connected to 5 sets of 910M, and each Getway can monitor up to 20 sets of 910M. System setting advantages:

1.3 4 RS-485 Ports can collect data from the lower 910M at the same time to increase the system response speed.

2 Other advantages:

2.1 Use the web page to set internal parameters and increase the number of 910M without installing additional software.

2.2 You can adjust parameters such as system transmission baud rate, parity check, transmission cycle, and repeated writing times in the web page settings to increase system flexibility and expansion capabilities.

2.3 When used in a more severe environment, the number of repeated writing can be adjusted to reduce the situation that the lower-end device does not receive data.

2.4 It has the function of hardware lock, which can be turned on after the adjustment of system settings is completed to prevent personnel from accidentally changing the internal parameter settings.

FFU control unit

The FFU control unit uses the single-chip microcomputer as the core processor to realize the control function. It is the terminal controller of the FFU. One FFU unit module controls one FFU or controls two FFUs in parallel. The FFU control unit can realize the following control functions:

(1) Control the start, stop and speed regulation of each FFU through the host

(2) Remote centralized control and fault diagnosis can be realized:

(3) Each control unit module has a settable ID address

(4) With overload and no-load alarm function: when overload and no-load, the FFU control unit will be prompted to give an alarm.

FFU Features

1 AC or DC FFU controller can be selected according to the motor type.

2 You can choose to set the IP address of each FFU by wire control or DIP switch according to your needs.

3 The motor over-temperature detection contact can be added as required to determine whether the motor operating temperature is abnormal.

4 It can monitor the current value of the fan when it is running to judge whether the fan is faulty or abnormal.

5 There are lights on the FFU controller, which can judge the fault status of the FFU on the spot.

Communication speed calculation method

1 910M to FFU communication speed calculation: 910M to 1 FFU communication time is 0.2 seconds, if 63 FFUs are connected, the communication time is 12.6 seconds.

2. The communication time of Getway to 1 910M is 8 seconds, if it is connected to 5 910M, the communication time is 40 seconds.

3 Getway If 4 RS-485 PORTs are connected to 5 910s, because 4 PROTs communicate with the lower 5 910Ms at the same time, the communication time is also 40 seconds, so it only takes 12.6 seconds to connect 1260 FFUs according to this calculation. +40 seconds, all FFU status can be sent back to the computer.

HMI host

The man-machine interface host adopts the display screen to realize remote monitoring and adjustment of FFU, which can easily realize the control of multiple FFUs and partitions, and can realize the start, stop and speed regulation functions of any number of FFUs, and the speed regulation function can be digitized, that is, Directly input the expected wind speed value (such as: 10%, 20%, etc.) to achieve the purpose of speed regulation, and can monitor the current of any FFU. When there is a faulty FFU alarm, it can display the location of the faulty FFU in real time. The computer monitoring center adopts the on-site interface mode, through communication with the monitoring host, when any one or more FFUs fail, the on-site interface of the computer monitoring center alarms, quickly determines the location of the faulty FFU, and ensures that the monitoring personnel deal with the fault in time.

Partition control mode

According to the needs of the actual system, each host is divided into six areas for control, and each area corresponds to a group of FFUs (the system stipulates that the number of fans in each group is at most 32), and the control functions are as follows:

1. Control the start and stop of a certain group of fans in the entire clean room, and can set the wind speed of a certain group of fans uniformly;

2. Control the start and stop of a fan in the entire clean room, and set the wind speed of a fan;

3. The number of fans in a group can be set;

4. Query the running status of a fan in the entire clean room, such as the start and stop status of the fan, and the running wind speed of the fan;

5. Overload protection function: When overload occurs, it will automatically alarm remotely.

Features of computer group control

The characteristics of computer group control: easy to control, can be adjusted speed, can realize more complex applications, using distributed control, can realize centralized control and monitoring of FFU; can realize the control of different systems of FFU sub-system, and can It realizes monitoring of a single FFU, and this method also has the effect of energy saving.

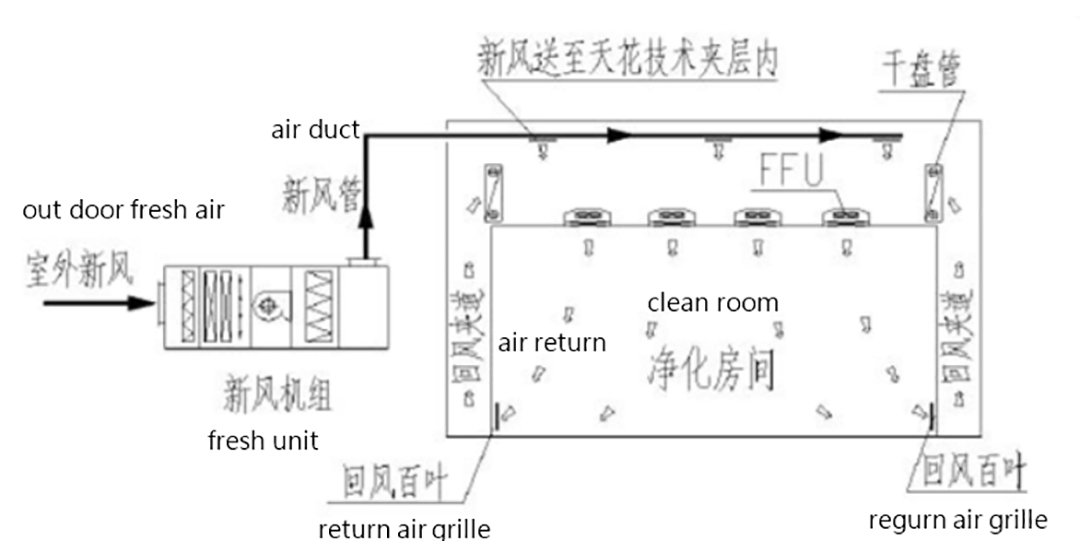

Common air conditioning methods using FFU

Fresh air unit + dry coil + FFU air conditioning mode. The so-called dry coil is because the refrigeration coil only bears the sensible heat load in this system, and the inlet temperature of the chilled water is generally above 13 °C, that is to say, the coil is generally impossible to generate above the dew point temperature of the indoor air. Condensate water belongs to dry operation, so it is called dry coil, and the commonly used method for producing chilled water at 13°C is to use a water-water plate heat exchanger to convert the chilled water at 7°C/12°C of the chiller. .

The so-called FFU, which means fan filter unit in Chinese, is a modular terminal air supply device with its own power and high-efficiency filtration function. Many purification equipment manufacturers have a detailed introduction of FFU, which will not be repeated here.

Fresh air unit + dry coil unit + FFU air conditioning method means that the outdoor fresh air is sent to the ceiling technology interlayer of the clean room after being processed by the fresh air unit. The dry coil unit is responsible for processing the air to the required parameters, and then uses FFU to circulate the air to achieve The air exchange volume required by the cleanliness, usually the fresh air unit treats the fresh air to the indoor dew point temperature, bears the fresh air load and the indoor humidity load, the dry coil bears the indoor sensible heat load, and the FFU load circulates and filters the air. That is, the fresh air unit is responsible for the humidity, the dry coil is responsible for the temperature, and the FFU is responsible for the cleanliness. The schematic diagram of the air conditioning mode is shown in Figure 1.

The practical feasibility of fresh air unit + dry coil + FFU purification air conditioning method

The initial investment of the fresh air unit + dry coil unit + FFU purification air conditioning method is not necessarily higher than the initial investment of the conventional purification air conditioning method of the fresh air unit + mixed fan unit + high efficiency filter. If the design is reasonable, the initial investment is often the same as that of conventional purification. The method is basically the same, but considering that the power consumption of the purification air-conditioning system in the electronic workshop is very large, the focus of a purification air-conditioning method should be placed on the energy consumption of the operation, and the number of shifts used in the clean room is basically the same. For continuous shifts, the purification air-conditioning equipment runs for a long time, so it is practical and feasible to choose a purification method with low energy consumption. Often a low-energy purification method can increase the initial investment within two to three years. Partially saved back. Therefore, the purification air-conditioning method of fresh air unit + dry coil + FFU is worthy of promotion and implementation.

FFU central monitoring system configuration instructions

FFU central monitoring system includes main control computer, graphic interface operation software, Active Gateway, FFU control panel, and can also integrate touch panel and manual controller according to site requirements.

A single monitoring system can connect up to 94, 500 FFUs, the graphical interface operation software is presented in a window interface, and the operation status of each FFU is represented by the on-site location graphic (color representation), which is convenient for management. It is easy to understand the on-site situation and can quickly identify Issue relevant control instructions;

The system adopts ActiveGateway Ethernet TCP/IP communication mode, and one IP field can connect 250 Gateways to FFU;

Active Gateway actively communicates directly with the FFU control board using RS-485 network control, which can connect 378 FFUs, which is instant and fast; ActiveGateway has the function of online monitoring of FFU, which can be directly displayed by a browser, and can be easily managed without a monitoring system use;

The FFU controller supports manual controllers and on-site touch panels, which can be used for FFU testing and maintenance operations on site, and the current rotational speed and FFU operating status can also be immediately obtained from the computer;

FFU offline mode can set four-stage or five-stage speed control for a single machine, which is convenient for monitoring the system and maintenance.

Introduction of clean room FFU fan filter air supply unit.

The full name of FFU in English is Fan Filfter, and the professional term in Chinese is fan filter unit.

The FFU fan filter air supply unit is widely used in clean rooms, clean workbenches, clean production lines, assembled clean rooms and local clean workplaces such as Class 100. It has the characteristics of modular connection and use.

The fan filter air supply unit FFU adopts the latest foreign technology to provide high-quality clean air for clean rooms and micro-environments of different sizes and different cleanliness levels.

The product is equipped with a fan inside, which is easy to install and maintain. It can be easily matched with any ceiling frame to meet the requirements of cleanliness class 100, 10 and 1. It is widely used in various industrial and biological clean rooms.

FFU (Fan Filter Supply Unit) adopts single-phase or three-phase high-efficiency, long-life, maintenance-free motor, and provides optional variable speed controller and electronic commutation electric motor, which can reduce energy loss and cooling load, Thereby reducing operating costs.

The high total static pressure value can be achieved at the rated air volume, and the low-resistance non-baffle filter, combined with the high total static pressure of the fan, can provide an external static pressure of 50 to 100PA under the rated airflow.

Technical parameters

| Model | QH-FFU-2000 | QH-FFU-900 | QH- FFU-600 |

| External Dimensions W*L*H(mm) |

4*4 |

4*2 |

2*2 |

| HEPA Filter Size | 1170*1170*69 | 1170*570*69 | 610*610*69 |

| Efficiency | ≥99.99%@0.3um | ||

| Construction | stainless steel SUS304 or Al-Zn Plate | ||

| Air Velocity(m/s) | 0.3-0.45 | ||

| Air Flow(CMF) | 1200-2000 | 900-1400 | 650-850 |

| Noise Level dB(A) | 52-58 | 50-56 | 50-56 |

| Voltage | AC 1P 220v/50HZ | ||

| Consumption(W) | Less than 200 | Less than 150 | Less than 150 |

| Weight(kg) | 55KG | 35KG | 28KG |

What we cannot make DC ffu, but also can supply FFU group control system solution for you with our professional technical.

Look forward to your inquiry.

+86-18038493642

+86-18038493642